ECOLOGY

Circular economy

Implementation of circular economy in the CHT Group

- Circular economy is anchored in our Strategy 2025 as part of the Roadmap Sustainability

- Circular economy is an important pillar on the way to climate neutrality

- Circular economy is a component of the EU Green Deal

Measures of the CHT Group

- Use of bio-based raw materials

- Use of recycled raw materials

- Development of products that are biodegradable or do not inhibit subsequent recycling

- Achievement of a Cradle to Cradle (C2C) Material Health Certificate for selected textile auxiliaries and textile dyes

- Increasing the reuse rate for plastic packaging by setting up container washing systems at CHT production sites or through service contracts with external providers

TUBINGAL RISE

With TUBINGAL RISE, CHT has successfully introduced the first textile softener based on recycled silicones and emulsifiers from renewable raw materials to the market. Its silicone oil consists of used silicone materials that have been converted into a recycled silicone oil via a complex treatment and cleaning process. The hydrophilic silicone softener can be applied to all textiles and provides a special core softness. Used on recycled fibers, the textile can be completely recycled again after use.

CHT-BEAUSIL RE-AMO

As an additive for the care industry, silicones in hair care ensure good combability, shine and softness. With CHT-BeauSil Re-AMO, a common silicone raw material has not only been modified using natural sugar variants, but it also consists of more than 90 percent recycled silicone raw materials.

As a manufacturer of silicone specialties, the CHT Group now supplies some of the recycled silicone raw materials itself. Common silicone raw materials contain silicone cyclenes from the preliminary processes – known as D4, D5 and D6 for short – which are largely removed from these raw materials by distillation. This distillate is not disposed of as waste but is used as a raw material in CHT’s silicone synthesis. In 2023, around 110 metric tons of raw materials were obtained in this way and ergo waste was avoided.

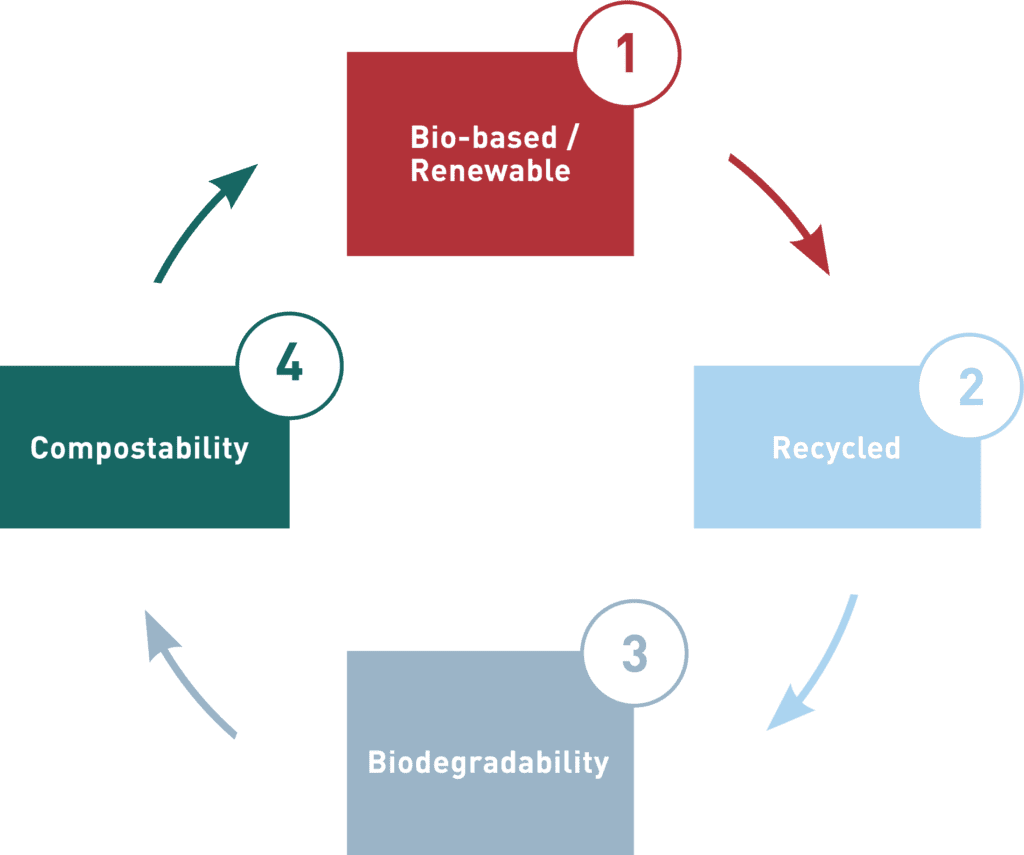

Below you can see the CHT terminology and test criteria defined for the most important topics in the context of the circular economy.

TERMINOLOGY OF THE CIRCULAR ECONOMY

Bio-based products are derived from plants, animals and other renewable agricultural, marine and forestry materials. CHT aims to use raw materials from sustainable cultivation.

Figures: percentage of bio-based materials in the product.

Recycled materials are products, materials or substances which are derived from waste. Waste is either recycled for the original purpose or up-cycled/down-cycled.

- Material recycling

Specification: percentage (mass) of recycled materials in the product.

Biodegradability is defined as the fact that a material can be biologically degraded in aqueous systems under anaerobic or aerobic conditions. Depending on the environmental conditions CO2, H2O, methane, biomass, and mineral salts are released in this process. Test criteria OECD 302B (aerobic) (elimination and mineralization). Criteria are fulfilled if more than 70 % are decomposed within 28 days.

- Yes/No criteria

Criteria for anaerobic degradation will be added if available.

Compostability describes the degradation process of organic materials via a microbial digestion by soil organisms for transforming these materials into compost.

CHT recommends testing compostability according to DIN CertCo.

DIN CertCo test criteria in accordance with DIN EN 13432 on final products such as e.g. T-shirts, coated paper, laminate floors, etc. All four criteria must be fulfilled:

- Degradation of 90 % after 6 months (DIN ISO 14855:1999)

- Max. sieve fraction of 10 %, more than 2 mm after 3 months

- Control of damage growth on compost, germination rate and vegetable biomass more than 90 % in comparison to blank compost

- Low heavy metal content and other toxic and dangerous substances (Zn < 150 ppm; Cu < 50 ppm; Ni < 25 ppm; Cd < 0.5 ppm; Pb < 50 ppm; Hg < 0.5 ppm; Cr < 50 ppm; Mo < 1 ppm; Se < 0.75 ppm; As < 5 ppm; F < 100 ppm)

Production of silicone masterbatches: increased energy efficiency at the Oyten plant

At the German plant in Oyten, a team reviewed all energy-intensive technologies with regard to process optimization and improved energy efficiency.

In 2022, the team, consisting of process, plant and production engineers and R&D, set out to optimize silicone masterbatches; the goal was to optimize the process in terms of energy usage.

Masterbatch production involves several sequences with significant increases in viscosity, as well as mixing and kneading phases at high viscosities. These phases are particularly energy-intensive and account for most of the total energy demand of batch production.

In the first step, the production process was significantly optimized in terms of the temperature profile and reaction sequence, and in a second step, the recipes were converted to automatic process sequences. This means that the PLC automatically drives the recipe sequence.

In the third, parallel step, the heating control was optimized. Overall, this measure resulted in energy savings (electricity) averaging 53 % per batch in masterbatch production.

The project was awarded the prize in the Responsible Care Competition 2023 by VCI Nord.